Benefits

MEASURABLE EFFECTS OF THE SYSTEM

If you are familiar with the concepts of #quality control, #quality management, #audit, #VDA 6.3, #ISO, #5S, #Lean, #Gemba Walk, #HACCP, #GHP, #GMP, #TQM, then the icmInspector system is just for you. 5 days is enough to implement our solution in your organization. Take a step into the future, introduce digital control, introduce process automation, gain up to 70% of the time previously spent on these processes. But that's not all, see other benefits offered by icmInspector.

Improvment of quality in the organization

Minimalization of operating costs

Increase the efficiency of employees

Eliminate errors, abuses and fraud

Planning in real time

Reduction of data analysis time

Automatic work scheduling

Online access to all data

Customers

They trusted us

International quality leaders chose the icmInspector system, which allows them to digitize the processes of quality control, audits and reviews. Every day, thousands of products are checked, which is quick and efficient, and the icmInspector system automates the detection of irregularities and then monitors the status of corrective and corrective actions. Join the quality leaders!

JMP Flowers

ELIS

FAKRO

Primavega

SOKOŁÓW

Smart Vegetables

Bispol

DAKO

DOBROPLAST

Green Factory

SWISS ROTORS

BZOMEX

Agro-Handel

POKUSA

SALPRONE

AGRANA POLAND

PILKINGTON

YOUR COMPANY

Functionality

Why our system?

Quality Management

- Building any control and inspection scenarios.

- Work scheduling for users and user groups.

- Automatic abnormality detection based on alarm templates.

- Reporting of control and inspection results.

- Analysis of control and inspection results.

- Registration of corrective actions.

- Generating PDF documents.

- Data export to CSV.

- Compliance with HACCP, GHP, GMP, ISO, IFS, and others.

Field Service Management

- Building any review scenarios.

- Scheduling work for users and groups of users and assigned to objects and devices.

- Reporting the results of reviews.

- Parts and materials warehouse.

- Accounting for parts and repair materials.

- Analysis of the results of reviews.

- Registration of corrective actions.

- Generating PDF documents.

- Data export to CSV.

Digital Work Instructions

- Building any scenarios and instructions for performing actions along with photo documentation.

- Presentation of scenarios on mobile devices and RealWear-assisted reality glasses.

- Reporting the time and sequence of scenarios and individual steps Analysis of the results.

- Generating PDF documents.

- Data export to CSV.

Scenarios building

- 19 step types including: List Select, List Multiple, Text and Number Input, Photo and Video, Screen Caption, Date, Email, GPS, QR Code Scan and NFC Scan

- validation of the answer

- dependent questions

- repetitive groups

- scores

- speech recognition

- copying and versioning scenarios

- no quantitative restrictions

Scheduling

- scheduling scenarios for persons and objects

- automatic planning of future events

- recurring events

- drawing work plans

- monitoring the implementation of the work plan

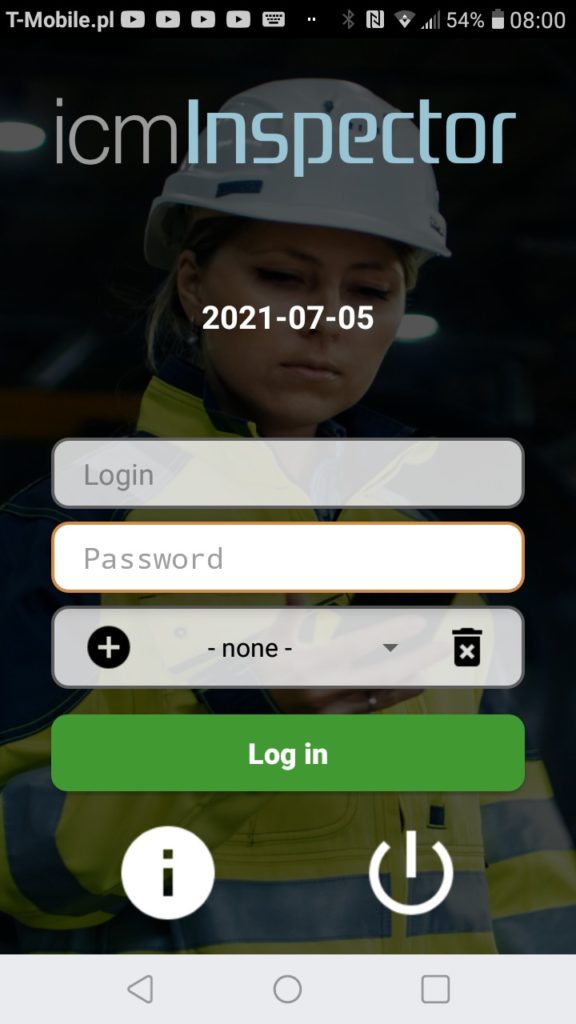

Mobile application for Android devices

- work on-line and off-line

- employee task calendar

- access to all assigned scenarios

- stopping work

- work history

- the ability to work in many virtual organizations

- cooperation with Bluetooth measuring devices (e.g. SYLVAC calipers)

- taking pictures and recording video

- speech recognition

- NFC codes and GPS location for confirming the workplace

Web surveys

- the ability to complete surveys via a web browser from desktop computers or mobile devices

- camera support

- filling in questionnaires without logging into the system

- no quantitative restrictions

Agumented Reality devices

- support for Augumented Reality devices

- application for Google Glass EE2

- app for RealWear HMT-1

Internet of Things module

- support for IoT (internet of things) controllers. automatic collection of data from production devices in terms of stocks (0/1), values (any numbers)

- automatic data analysis and notifications about irregularities

- automatic report wizard with the possibility of sending e-mails

- BacNET communication

- large pool of sensors and measuring devices

Reporting

- automatic creation of reports (HTML, PDF) with GPS maps, photos and recordings. summary reports (HTML, PDF). analytical reports with charts (HTML, PDF)

- data tables (CSV)

- notifications about data collection (e-mail, SMS)

- notifications about the failure to implement an action (e-mail, SMS)

- automatic distribution of reports by own schedules

- own reports (wizard)

- work reports (subject, places and working time)

Analytics

- built-in analytical and tabular reports

- managerial dashboard

- bar, pie and line charts

- summary reports with the auto dispatch wizard

- alarm module with e-mail and SMS notifications

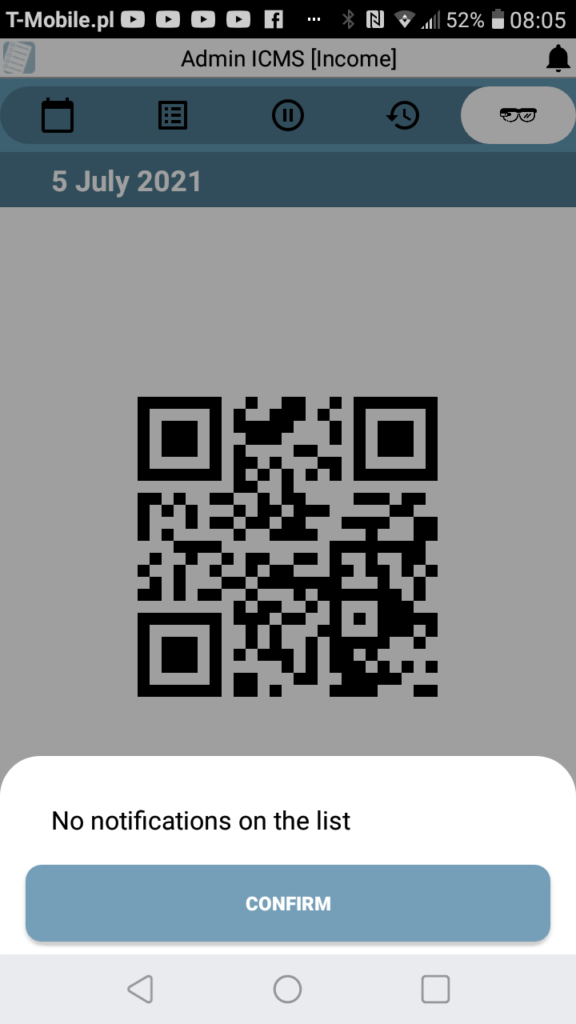

Alerts

- wizard of any alarms and notification scenarios of irregularities

- automatic email and SMS notifications without having to view all reports

- setting up and commenting on events and detected alarms

- history of corrective and corrective actions

- configurable no-action reminders for detected irregularities

Simple price list, no hidden fees

Do you need more information? Write to our consultants via chat.

| Cloud |

| 1 GB data per user (2) |

| no installation costs |

| no upgrade costs |

| help-desk on-line |

| FROM 37 EUR for 1 user per month (1) Choose |

| On-premise |

| no data limit |

| installation fee (3) |

| upgrade fee (4) |

| help-desk on-line |

| from 33 eur for 1 user per month (1) choose |

(1) The prices quoted are net prices. the prices quoted refer to a subscription for 3 months payable in advance.

(2) Each additional 1GB of data costs 1.50 EUR net per month.

(3) The cost of remote installation and configuration of the system in the Client's resources is 750,00 EUR net.

(4) The cost of remote installation of system updates in the Client's resources is 125.00 EUR net.

Inquiry

Provide us with your details and any comments. We will contact you regarding the details of the order.

Articles

The 5 WHY method

The 5 WHY method is one of the methods to detect the causes of problems. This is the principle we use to determine the root cause of the problem. Asking a few "Why?" questions allows you to get to the source of the disruption, thoroughly investigate the cause, and focus on solving it effectively.

New version of the system

The new version of icmInspector introduces more than 20 changes and corrections to the previous functionalities. We have introduced new types of questions and tools for increasing the reliability of inspections using NFC cards for employees. We are constantly trying to make every quality control and inspection performed with icmInpector faster and more accurate.

RPA in Quality Control?

RPA (Robotic Process Automation) is a set of ICT solutions enabling the automation of, among others, repetitive business processes. The group of such tools includes physical robots performing repetitive activities (e.g. in production, storage), but also applications and modules that automate repetitive tasks based on known rules, which were previously performed manually by a human, system user or process actor.

How does icmInspector protect us against the effects of COVID-19?

Every company has been affected in some way by the effects of the COVID-19 pandemic. Each company also began to take measures to minimize the threats that began to appear as a result of COVID-19. The icmInspector system is a tool that, in certain areas, perfectly helps us protect ourselves against certain threats, and more precisely with the effects of sudden and temporary absences of employees from the company.

Contact

Producer

icMobile System sp. z o. o.

Al. J. Piłsudskiego 46

33-300 Nowy Sącz

+48 694 412 203

icmobile@icmobile.pl

BECOME OUR PARTNER!

If your company provides solutions for food or industrial production entities, we will be happy to establish a partnership! You can find more about the cooperation model in the For partners section.

Email us: partners@icmobile.pl

Sale

-

icMobile Systems Sp. z o.o.

Al. J.Pisłudskiego 46

33-300 Nowy Sącz -

KOGNITA Sp. z o.o.

Al. Rzeczypospolitej 20/96

02-972 Warszawa -

SYMATIC SP. Z O.O.

ul. W. Trylińskiego 8/L1

10-683 Olsztyn -

IBCS Poland sp. z o. o.

Al. J. Piłsudskiego 46

33-300 Nowy Sącz -

SZKOŁA JAKOŚCI

ul.Strażacka 25F/5

35-312 Rzeszów -

COM4IT Sp. z o.o.

ul. Józefa Piłsudskiego 3

43-300 Bielsko-Biała